APR R8 4.2L FSI V8 Stage III+ TVS1740 Supercharger System

APR is pleased to present the R8 4.2L FSI V8 Stage III+ TVS1740 Supercharger System!

APR’s technical reach has grown enormously since opening in the 1990’s and currently represents a force of unmatched performance without compromise in the performance enhancement sector for Audi vehicles. Our previously available APR Stage III TVS1320 Supercharger System found its way on to several hundred 4.2L FSIs around the world, making it the most popular and reliable system on the market. With more than four years' worth of 4.2L FSI supercharger engineering research, development and testing, APR’s new Stage III+ TVS1740 Supercharger System represents the pinnacle of Audi’s German engineering enhanced by APR’s American ingenuity.

In the factory form, Audi’s high revving FSI V8 can leave much to be desired compared to some of the latest technological advances brought forth by Quattro GmbH in recent years. The APR Stage III+ TVS1740 Supercharger System fills the void by adding an average of roughly 46% more horsepower and torque across the entire power band. The results are nothing short of amazing; taking the R8 from 425 horsepower to 642 horsepower on pump fuel and 689 horsepower on race fuel without breaking a sweat! With 550 FT-LBS on tap thanks to the TVS1740’s positive displacement supercharger, expect instant acceleration with absolutely no lag commonly associated with other forms of forced induction.

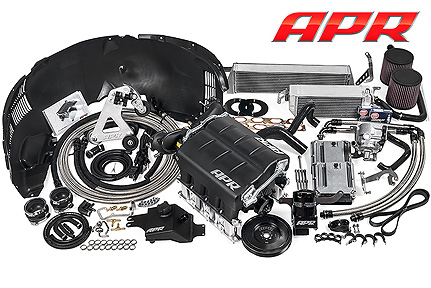

APR Stage III+ TVS1740 Supercharger Components

To learn more about each piece of the APR Stage III+ TVS1740 Supercharger System, please click on the images below for more details.

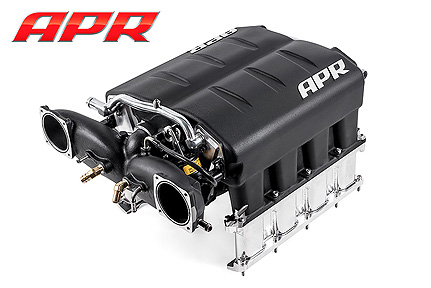

Supercharger, Manifold and Runners

At the heart of the APR Stage III+ Supercharger System is Eaton’s latest Twin Vortices Series (TVS) supercharger unit, the TVS1740. The supercharger system is a positive displacement, roots style pump, utilizing Eaton’s lightweight, four-lobe 160 degree twisted rotors. Cast and assembled as a single, OEM-style-manifold and rotating group housing, the unit is quiet, compact, attractive, easy to install, and requires little to no extra maintenance to the unit itself.

The positive displacement supercharger offers power instantly as the throttle is pressed. Boost pressure builds with no perceived lag commonly associated with other types of forced induction, and provides a large increase in torque across the entire power band. Throttle control is linear and predictable and makes for an excellent driving experience both in daily driving and wide-open acceleration.

Since the supercharger does not compress air as it moves through the roots, it’s extremely efficient during light throttle and cruising situations. Unlike screw-type positive displacement superchargers that are always compressing, the TVS unit can internally bypass unwanted air, resulting in negligible parasitic loss during cruising and thus far greater fuel economy.

The single cast unit and appropriately sized rotating group eliminates potential leak points and allows for a slim, compact design without sacrificing key airflow design characteristics. The unit features a high velocity flow path through the supercharger rotors and an unrestricted discharge port into the appropriately sized plenum. The large plenum equalizes flow across all ports as air feeds evenly through the low-pressure-drop, dual-internal air-to-water heat exchangers. Finally, the ports are separated into individual runners and continue through aircraft grade 6061 billet aluminum extension runners, offering greater operation by eliminating cross talk.

Internally the dual heat exchangers offer technological advances shared by Formula 1 teams around the globe. Each unit features a louvered fin design, which minimizes pressure drop while achieving excellent cooling effectiveness. The extruded multi-rib tubing maximizes heat extraction to be carried away through the large bore coolant recirculation hard lines. Externally, supercharger coolant is pumped through a large front mounted heat exchanger where it’s cooled and circulated back through the charger again.

| Next Component →

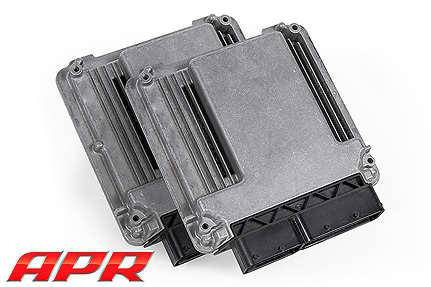

Engine Management

The factory Bosch MED 9 engine management system is responsible for proper operation of the engine during constantly changing environmental and load conditions. With built in compensational data for environmental variables and varying load conditions, the factory ECU is far more complex and intelligent than units found in other vehicle makes and marques.

With the significant amount of changes included in the APR Stage III+ TVS1740 Supercharger System, APR’s Engineers spent months calibrating the engine management system, including well over 100+ hours of in-house chassis dyno development. Drivability, gear changes, cruising and part throttle operation were tuned to operate smoothly as if intended by the OEM. Further development was performed putting the vehicle through performance evaluation and durability testing at the drag strip. APR’s Electrical Engineers built new coding functions, strategies and routines into the ECU to control conditions normally unseen at factory power levels. Thanks to APR’s incredible proprietary calibration suite, data logging software and full access to the coding structure of the ECU, appropriate and intelligent changes are made to ensure flawless drivability and excellent performance without compromise.

Adding forced induction to a naturally aspirated engine presents several challenges with regards to how the ECU operates. APR’s Calibration Engineers properly restructured the engine’s volumetric efficiency (VE) model to properly determine the ECU’s calculated load. Accurate open loop fueling is achieved, translating to insignificant fuel trim adjustments. Closed loop fueling is calibrated to control lambda perfectly under all operating conditions. Furthermore, compensations, such as ones related to intake air temperature, are adjusted to handle the large temperature variances compared to a factory naturally aspirated setup.

APR’s Calibration Engineers have optimized cam timing, ignition timing and lambda to provide tremendous leaps in power while retaining OEM knock control sensitivity. The result is safely achieved power, optimized for various fuel grades found around the world from low quality pump fuel, all the way to high quality, oxygenated race fuels.

Beyond power and torque enhancements, APR’s Calibration Engineers were able to increase the acceleration rate of the vehicle through other calibration changes. Ignition delays are reduced resulting in a more responsive pedal without altering overall throttle sensitivity and resolution. Drivability was greatly improved by reducing the throttle lag commonly noticed at slow speeds and while reapplying throttle after decelerating. APR’s Motorsport Rev Limiter allows power to climb all the way to the factory set redlines without dropping off several hundreds of RPM earlier. And lastly, APR’s tried and tested 4,200 RPM Motorsport Launch Limiter allows the driver to focus on launching the vehicle, rather than controlling the engine speed.

Beyond wide open throttle performance, APR’s Calibration Engineers spent countless hours optimizing vehicle drivability under daily, part-throttle, driving. The vehicle’s pedal maps are recalibrated under both standard and sport mode, providing smooth part-throttle drivability without compromising the driveshaft windup protection. The vehicle fully retains its impressive daily driver status and simply has more power on tap should the driver request more with his or her right foot! We call it Performance Without Compromise.

← Previous Component | Next Component →

Supercharger Coolant Air-to-Water Radiators

APR’s supercharger system features a large, 585 mm x 140 mm x 65 mm front mount radiator and a second 320 mm x 140 mm x 90 mm side mounted radiator responsible for cooling coolant as it’s pumped out of the supercharger’s dual internal air-to-water heat exchangers. An adequate cooling system is critical in any supercharged application to not only keep power consistent, pull after pull, but also to help keep IAT below dangerously high levels.

The heat exchangers are specific to the R8 platform and feature cast aluminum end tanks with threaded connection points and bleeder valves. Each cooler cleanly installs with the supplied CNC, laser-cut brackets, complete with vibration insulators.

← Previous Component | Next Component →

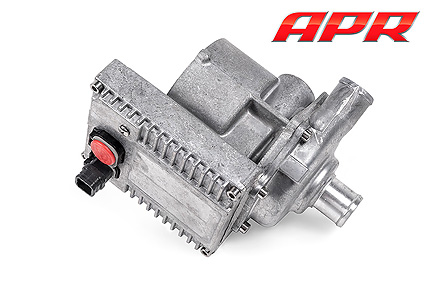

Supercharger Coolant Pump, Harness and Bracket

The R8’s rear mounted engine results in a supercharger cooling circuit spanning over twenty feet and calls for a high quality coolant pump. As such, APR’s supercharger cooling system features a highly efficient brushless cooling pump that feels right at home in the R8’s engine bay.

The military grade coolant pump seamlessly connects to the factory wiring harness through the included APR wiring harness with no wire splicing and is triggered by the included relay system.

APR’s CNC, laser-cut bracket provides a simple and clean method of mounting the pump to the vehicle, out of sight, and vibration isolators ensure the system runs as quietly as possible.

← Previous Component | Next Component →

Supercharger Coolant Expansion Tank

The APR coolant expansion tank is used for filling the supercharger’s cooling circuit and for handling liquid expansion under various operating temperatures. APR’s CNC, laser-cut bracket provides a simple and clean method of mounting the expansion tank to the engine bay out of sight. The alumnium tank is anodized black and features a machined APR logo.

← Previous Component | Next Component →

Supercharger Coolant Lines

The APR Supercharger System features dual internal air-to-water radiators designed to reduce intake air temperature, (IAT), before entering the cylinders. With cooler IAT, the ECU will request more ignition advance and result in more power.

A multitude of coolant lines feed the supercharger’s internal cooling system, which provides a circuit between the included radiators, coolant pump and expansion tank. Longer lines, such as those running the full length of the car, feature threaded connections, braided stainless steel outer sleeves and reinforced rubber cores. Specifically routed hoses are made from multi-ply silicone and the remaining hoses are flexible, reinforced rubber. All necessary brass connectors, spring-loaded clamps and OEM style crimp clamps are included.

The factory engine coolant hose running beneath the supercharger is modified for fitment reasons and is constructed from a high quality, multi-ply silicone. Protective covers are provided to shield against abrasion.

← Previous Component | Next Component →

Intake System and Air-Oil Separator Bracket

Two high flow K&N filters are adapted to the factory air box to provide fresh filtered air to the supercharger. The factory MAF housing bolts to the metal filter bracket and connects to the throttle body via two multi-ply silicone hoses. The ultra-ridged design ensures the hoses will not collapse under the tremendous vacuum created by the supercharger system’s newly added forced induction.

Laser-cut, CNC-bent air-oil separator brackets reposition and secure the factory PCV system beneath the intake system.

← Previous Component | Next Component →

Supercharger Pulley System

The supercharger system’s internal rotors are rotated via a belt and pulley attached to the engine’s accessory drive system.

APR’s upgraded the R8’s belt system to utilize a 6pk belt for additional strength. A new cast and CNC machined bracket is used to properly orient the circuit and features new OEM tensioners, and idler pulleys. The harmonic balancer is upgraded to an OEM replacement, high quality, balanced 6 rib unit.

← Previous Component | Next Component →

Engine Oil Relocation System

The APR supercharger system’s casting features a large, high flow, dual throttle body inlet system, which provides a high velocity flow path to the supercharger roots. To incorporate this feature into the design APR’s engineers were required to move the factory oil filter.

A CNC-machined billet-aluminum adapter connects to the oil feed and return and provides a connection point for high quality, braided stainless-steel oil lines. The lines route to the new black-anodized CNC-machined billet-aluminum oil filter housing.

CNC, laser-cut brackets cleanly hold the housing in place and out of sight under the factory engine side covers. Oil changes are now made easier with quick and easy access to the filter.

← Previous Component | Next Component →

High Pressure Fuel Pumps

Sold separately as brand new pumps or rebuilds of the engine’s existing pumps, the APR High Pressure Fuel Pumps address fueling needs and leave plenty of headroom for safety and further increased power levels. By increasing the pump’s internal capacity, the fueling system is capable of displacing a higher volume of fuel per minute at every RPM. Read more on our APR High Pressure Fuel Pumps product page.

← Previous Component | Next Component →

Fueling System

To accommodate the large APR Supercharger, modifications are made to the low-pressure fueling system and evap lines. Each fuel line exceeds CARB and EPA ratings and includes a patent-pending GreenShield barrier. The multi-ply, reinforced rubber hoses are designed to protect against today’s modern deteriorating fuels and include a best-in-class working psi of 225.

OEM style spring clamps and crimp clamps are included to ensure a solid connection. The included mounting bracket allows for a clean and solid install of relocated components.

← Previous Component | Next Component →

Intake Air Temperature Sensors and Harnesses

The factory mass airflow sensors include intake air temperature (IAT) probes and are designed to provide the engine control unit (ECU) with air temperature information. Because the R8 is converted from naturally aspirated to forced induction, the sensors must be relocated to ensure proper IAT measurement. The IAT sensors are absolutely critical for safe, reliable and powerful operation and as such, APR provides two OEM sensors and harnesses for placement just past the supercharger’s dual internal air-to-water radiators. The included harnesses allow for simple integration into the OEM wiring harness and come preinstalled in the supercharger.

The sensors feed correct IAT readings to the ECU, which provides closed loop control over various calibration decisions, such as desired ignition advance. This provides safe operation no matter what the condition. During a cold day, with lower supercharger coolant temperature, the ECU will safely increase engine output mainly through ignition. However, under hot conditions, such as a vehicle seeing plenty of track time, the ECU will compensate for these conditions, lowering output slightly to avoid dangerous premature detonation. These compensations result in only attempting to safely achieve the maximum amount of power capable during any given temperature related scenario.

← Previous Component | Next Component →

Engine Coolant Hose

The APR Supercharger fills the valley between the cylinder heads and as such, the factory coolant hose was redesigned to accommodate the supercharger. The specifically routed hose is made from multi-ply silicone and features a protective cover to provide a shield against abrasion.

← Previous Component | Next Component →

Vaccum Lines

To accommodate the transition from naturally aspirated operation to forced induction, APR provides new vacuum lines and junctions. Leak proof connections are easily achieved thanks to the included OEM style crimp clamps.

← Previous Component | Next Component →

Spark Plugs

To cope with raised cylinder pressure and temperature, eight NGK Iridium IX spark plugs are included. The plugs operate at a heat range colder than stock, which results in better pre-detonation resistance under extreme conditions. With these spark plugs in, APR’s calibration engineers were able to safely achieve more power, especially in extremely demanding conditions.

← Previous Component | Next Component →

Gaskets and Hardware

New OEM gaskets and bolts are provided to facilitate a leak proof connection between the cylinder heads and APR Supercharger runners.

← Previous Component | Next Component →

Fender Liner

The side blades on the Audi R8 provide an excellent mounting location for further supercharger air-to-water radiators. The APR Supercharger System utilizes a vented R8 V10 fender liner to allow proper airflow through the air-to-water radiator and in doing so, borrows an engineering design element from the V10 platform. The fender liner installs cleanly without any destructive trimming to the factory parts.

← Previous Component | Next Component →

Install Manual

APR has a worldwide network consisting of many professional shops capable of performing an APR supercharger system install. To accompany APR’s world-class technical support hot line, APR includes a full, printed, step-by-step install manual to make the install process smooth and simple!

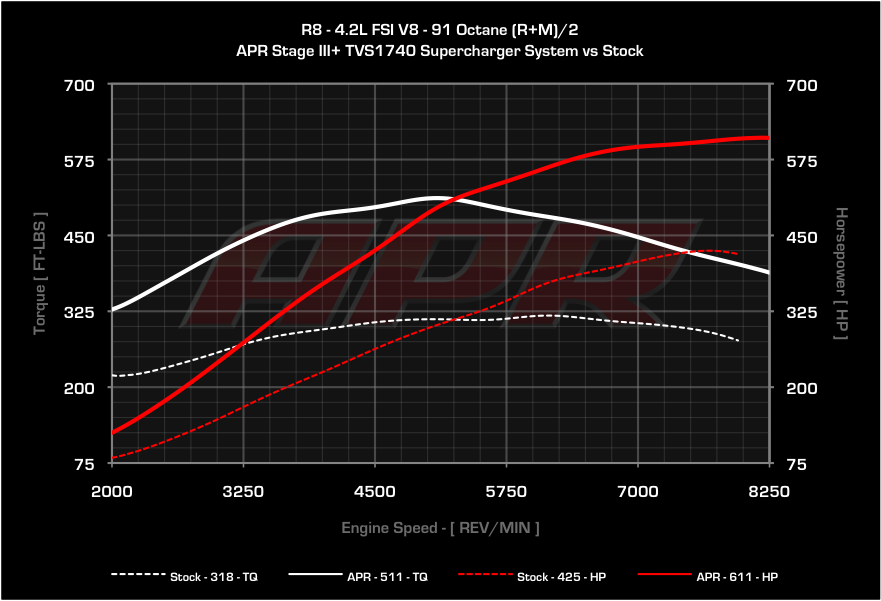

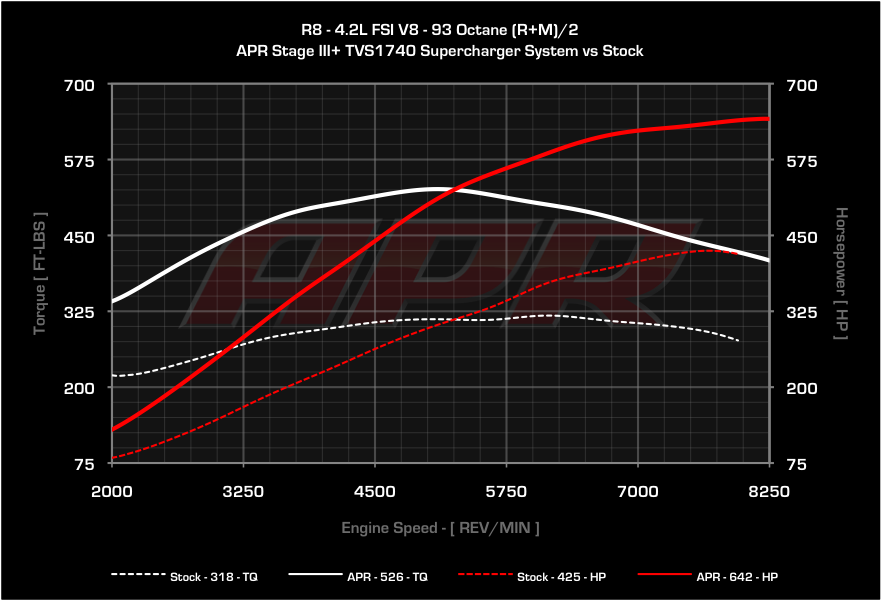

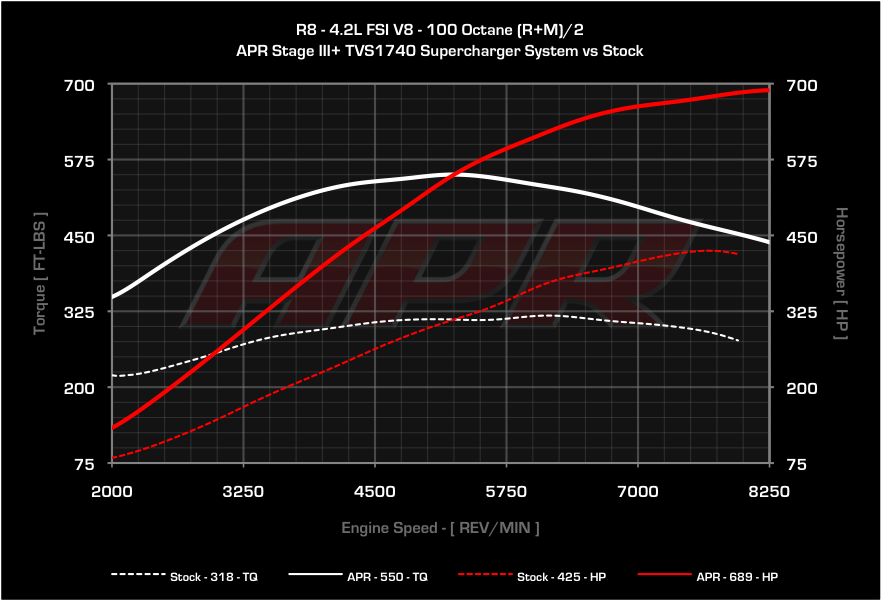

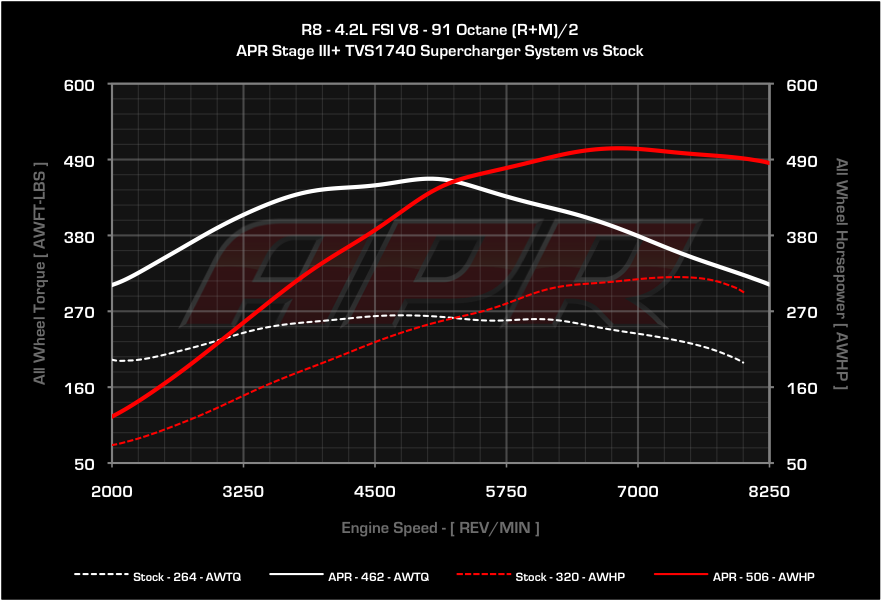

Dyno Testing

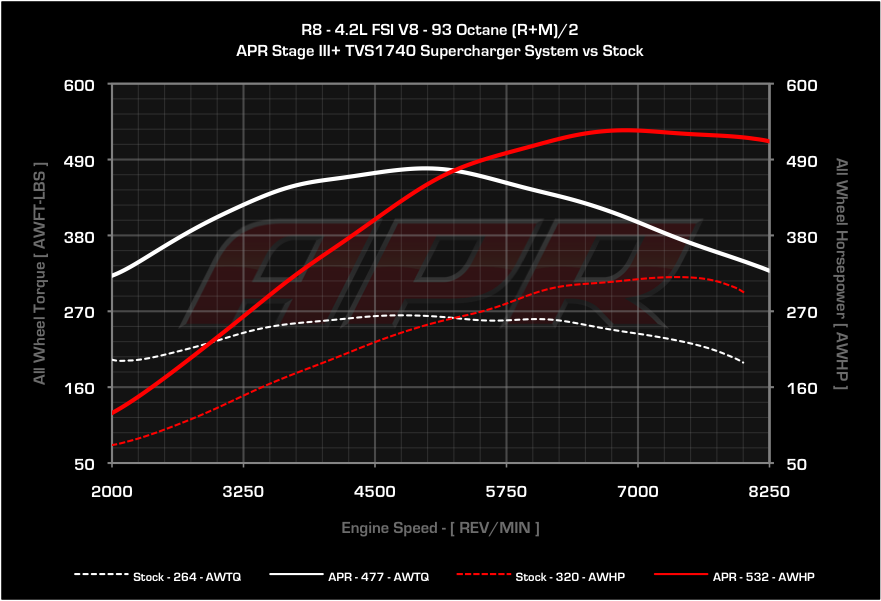

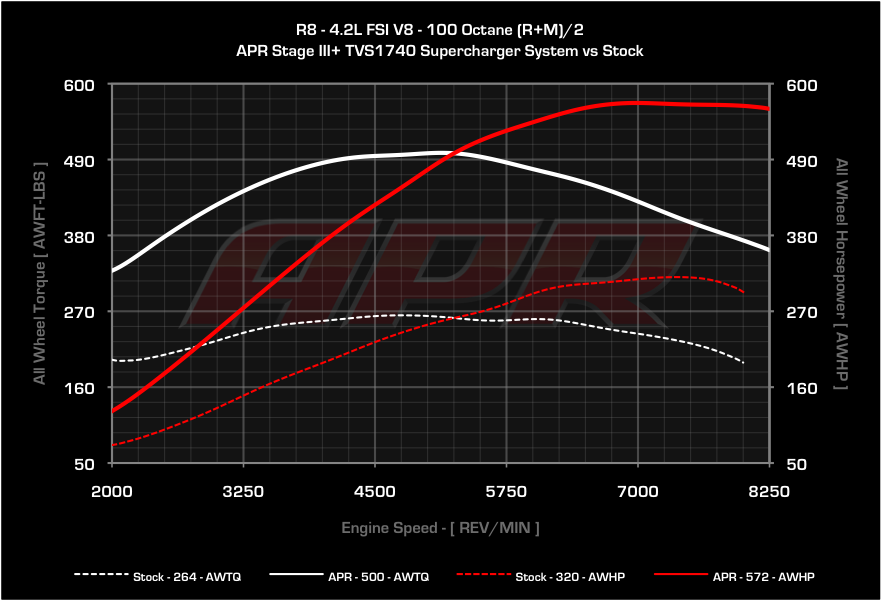

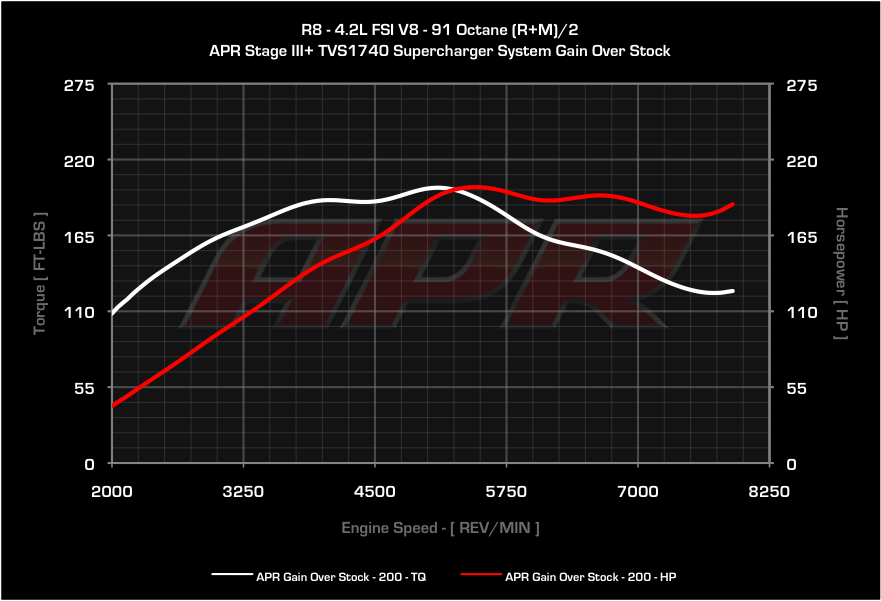

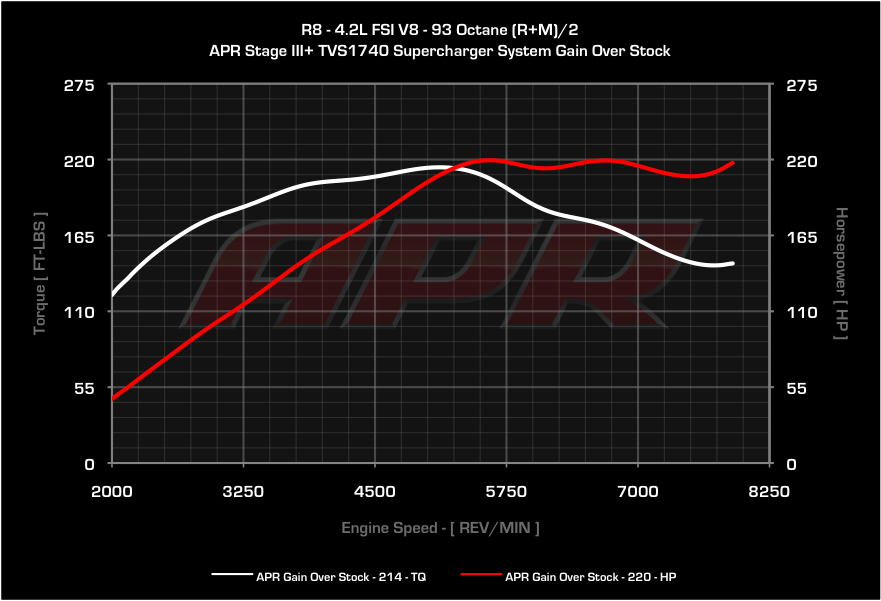

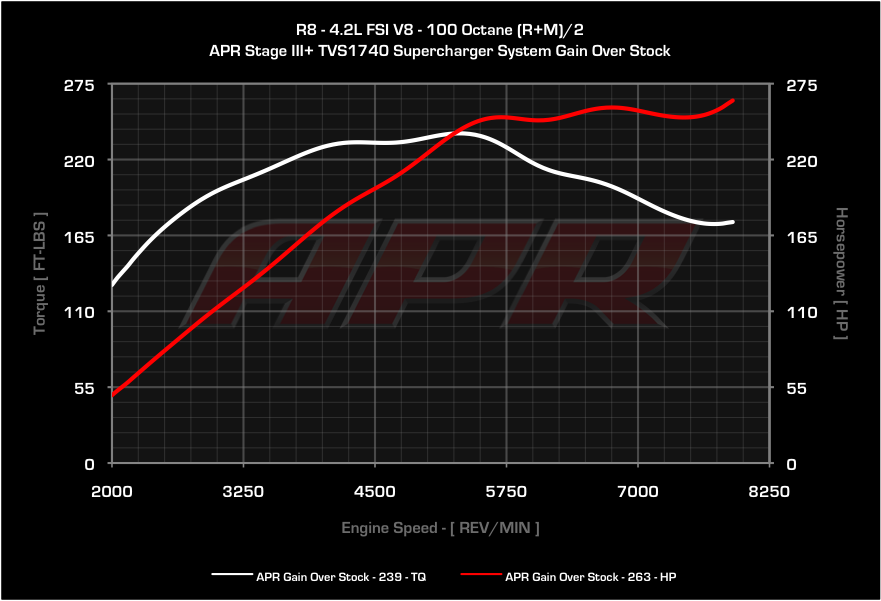

Horsepower and Torque were measured in APR’s in-house, soundmaster dyno cell, using a dynapack all wheel drive dynamometer. Multiple stock and modified runs were conducted and the SAEJ1349 corrected results were averaged together to represent the differences between a stock and APR Stage III+ R8. Crank power figures were estimated based on Audi’s factory advertised results.

Click through the tabs below to view output using various fuel grades, power measured at all four wheels, estimated at the crank, and the absolute gain over stock.

- Stage 3+ 91 CHP

- Stage 3+ 93 CHP

- Stage 3+ 100 CHP

- Stage 3+ 91 AWHP

- Stage 3+ 93 AWHP

- Stage 3+ 100 AWHP

- Stage 3+ 91 Gain Over Stock

- Stage 3+ 93 Gain Over Stock

- Stage 3+ 100 Gain Over Stock

| Stock As Rated by Audi |

Stock 93 AKI As Measured by APR |

91 AKI 95 RON |

93 AKI 98 RON |

100 AKI 104 RON |

|

|---|---|---|---|---|---|

| AKI - Anti Knock Index or (RON+MON)/2 for Octane Ratings | RON - Research Octane Number for Octane Ratings | North American Model | |||||

| Rev Limiter | 8,250 RPM | 8,250 RPM | 8,250 RPM | 8,250 RPM | 8,250 RPM |

| Speed Limiter | Limited | Limited | Unlimited | Unlimited | Unlimited |

| Peak Mechanical Horsepower (HP) | 424 HP | 425 HP | 611 HP | 642 HP | 689 HP |

| Peak Torque (FT-LBS) | 317 TQ | 318 TQ | 511 TQ | 526 TQ | 550 TQ |

| Max Horsepower Gain over Stock (HP @ RPM) | +200 HP @ 5,350 RPM | +220 HP @ 5,600 RPM | +263 HP @ 7,900 RPM | ||

| Max Peak Torque Gain over Stock (FT-LBS @ RPM) | +200 TQ @ 5,100 RPM | +214 TQ @ 4,950 RPM | +239 TQ @ 5,900 RPM | ||

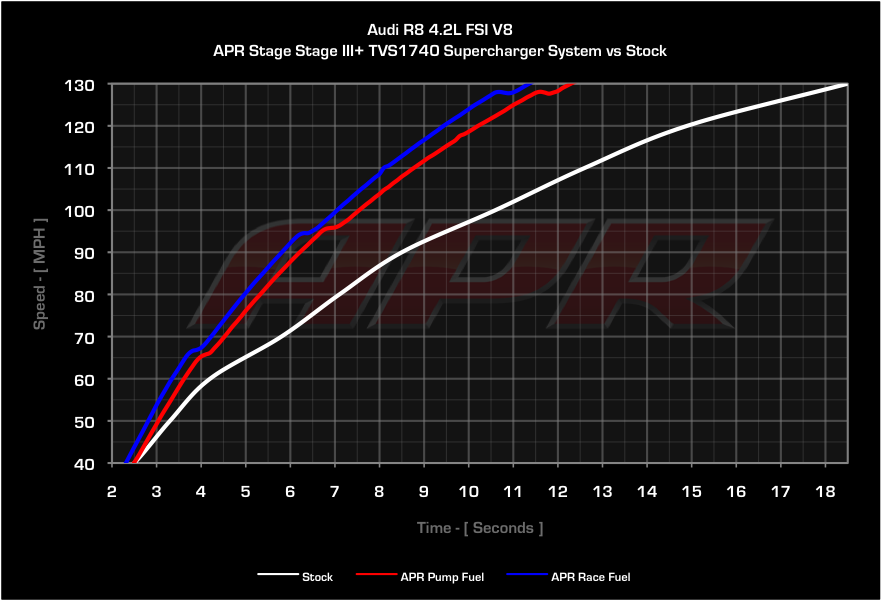

Acceleration Testing

All too often performance upgrades show improvements during a single dyno pull, but lack the ability to show the same performance in real world conditions. Furthermore the dyno may be unable to illustrate the system’s response and other tuning changes designed to make the system instantly react to the drivers input. Through acceleration testing, APR’s engineers were able to improve power delivery during launches, after gear changes and prove the cooling system was up to the task of shedding heat to keep power consistent.

APR’s local certified quarter mile drag strip is a perfect and safe testing ground for high speed, 130+ MPH sprints. Using Car and Driver magazine’s measured results as a benchmark, APR’s Engineers set out to prove the Stage III+ Supercharger System was capable of increasing the R8’s performance substantially.

Car and Driver magazine measured the R8’s sprint from 30-130 MPH in an underwhelming 17 seconds. However, with the addition of the APR’s Stage III+ TVS1740 Supercharger System, the vehicle entered a league of performance often shared by exotic supercars. Using 93 octane fuel the same acceleration test was completed 6.5 seconds faster! Through testing higher octane fuels, and eventually weight reduction and tire changes, the gap grew even larger, ultimately resulting in an astonishing 44% reduction in time.

Many more acceleration tests were performed, including record setting quarter mile passes, proving an APR Stage III+ TVS1740 Supercharger System is the ultimate upgrade for R8!

| Vehicle Stage | 0-60 MPH | 0-62 MPH | 0-100 KPH | 0-100 MPH | 60-120 MPH | 62-124 MPH | 100-200 KPH | 60-130 MPH | 30-130 MPH | 1/4th ET | 1/4th Trap |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Stage III+ acceleration data collected with a Race Logic P-Box. | |||||||||||

| Stock (Car & Driver Magazine) | 4.200 | - | - | 10.600 | 10.700 | - | - | 14.300 | 17.000 | 12.8 | 110 MPH |

| STG 3+ 93 AKI Full Weight & Street Tires |

3.618 | 3.745 | 3.754 | 7.547 | 6.572 | 7.081 | 7.111 | 8.695 | 10.491 | N/A | N/A |

| STG 3+ 100 AKI Full Weight & Street Tires |

3.345 | 3.452 | 3.475 | 7.052 | 6.038 | 6.475 | 6.506 | 7.884 | 9.562 | N/A | N/A |

Requirements and Recommendations (Each Sold Separately)

- APR High Pressure Fuel Pumps

The APR HPFPs expands the 4.2L FSI V8's direct injection fueling capabilities to the levels required for proper operation with the APR Stage III+ TVS1740 System. Because the pumps are sold in two different forms, they are offered separately from the kit. Entirely new pumps can be purchased, or the vehicle's existing pumps can be sent to APR for a rebuild at a discounted rate. This product is required. Product Page: APR HPFP. - Transmission

The APR Supercharger System greatly increases torque over the factory output levels and as such, an upgraded clutch may be necessary to transmit power to the ground. APR highly recommends upgrading the factory clutch to one that suits the operator's intended driving style. - Induction System

The APR Supercharger System was designed using the factory intake system with the included K&N Filters and OEM mass airflow (MAF) sensor housings. An intake port carbon cleaning is necessary to meet advertised power levels. - Exhaust System

The APR Supercharger System was designed for operation with the either the factory exhaust system or a high flow exhaust system.

| Vehicles | Transmission | System | Part | Price(税別) |

|---|---|---|---|---|

| R8 Coupe | 6MT (R-Tronic & S-Tronic to be announced) | APR R8 4.2L FSI V8 Stage III+ TVS1740 Supercharger System - Includes Software | T3100054 | ¥3,700,000 |