APR EA888 2.0 TSI Connecting Rods

APR is pleased to present Light-Weight, High-Strength Forged Connecting Rods for the EA888 2.0 TSI engine!

As the leader in high performance engine products for the Volkswagen Automotive Group, APR is capable of creating horsepower and torque levels outside of the original equipment’s stress tolerances. In such cases, it’s highly recommended and in some cases necessary to upgrade additional engine components to cope with the increased load. APR’s Connecting Rods raise the engine’s stress tolerance levels to provide years of continued reliable operation without compromise.

APR’s proprietary connecting rods feature premium, certified USA-Made 4330 alloy, chosen for its lightweight and high-strength properties compared to 4340 or other inferior alloys sourced from undisclosed locations around the world. To ensure the highest level of quality control, the entire process from initial design to finished product, including materials, forging, treating and 100% CNC machining all take place in the USA. APR only uses strict manufacturing guidelines in some of the finest manufacturing facilities in the industry to deliver unmatched quality and integrity with each rod produced.

Quick Facts

Strong weight saving design

Additional wear resistance

Surface finishes with consistent RA

Improves metal quality

Improves strength

Additional weight savings

High strength and light weight alloy

Casting quality control

Increased reliability & performance

Improves strength

Improves quality and control

Works with no other modifications

Exceptional wear resistance

Hardness testing

OEM quality fit

Improves fatigue strength

Materials, forging, treating, etc

High quality and strength bolts

The connecting rod is designed to handle power levels far beyond the original component’s ratings in order to ensure reliability with years of continued use. Increasing rod strength often comes at the expense of increased weight, which ultimately reduces engine efficiency. To generate a balance between strength and weight, APR tested and analyzed several designs in addition to using premium alloys, advanced forging techniques and multiple strengthening treatments. APR’s Engineering Team’s design requirements resulted in a tapered H-beam design, offering exceptional strength due to the H design and weight savings from tapering, a trait most commonly associated with an A design.

We call it Performance Without Compromise.

| Part Number | Engine | Engine Codes | Wrist Pin | Weight | Type |

|---|---|---|---|---|---|

| Weight includes APR2000 hardware. | |||||

| *Most engines built before May 2011 contain connecting rods with 21mm wrist pins while most built after May 2011 contain 23mm wrist pins. Please verify prior to purchase. | |||||

| MS100050 | EA888 TSI | CAW*, CBF*, CCT* & CCZ* | 21mm | 429.3g | Drop In for OEM Piston |

| MS100053 | EA888 TSI | CAW*, CBF*, CCT* & CCZ* | 23mm | 503.2g | Drop In For OEM or APR Piston |

The wrist pin end of the rod features a wear resistant bushing material made from AMPCO 45 - a high strength alloy with mechanical properties beyond that of commercial nickel-aluminum bronzes. Wear reduction is further enhanced via a pin lubrication access point at the top of the rod, feed by the engine’s oil squirters. For further weight reduction and drop in rod compatibility with OEM and APR pistons, the wrist pin end is tapered.

When modifying an engine for strength and longevity, quality is of the utmost importance. APR’s Engineering teams have ensured each rod is created with absolute quality and control in mind each step of the way. Tolerances are kept to OEM specs and the rods are balanced to within +/- 1 gram. Furthermore the rods undergo rigorous tests to backup the entire manufacturing process. Rockwell testing provides a method for testing hardness while Magnaflux or Magnetic Particle Inspection, offers a method for detecting interruptions in the physical continuity of the casting. The result is a product you can trust.

Mahle Motorsport VP2 Rod Bearings

When upgrading connecting rods, it’s necessary to replace the existing connecting rod bearings. APR recommends using Mahle Motorsport VP2 rod bearings for their superior strength and wear resistance properties and attention to detail over the similarly priced OEM bearings.

Each bearing is capable of taking abuse in the magnitude of 14,500 psi while still offering superior conformability and fatigue resistance not commonly seen elsewhere in the market. This is partially due to the bearing’s high-grade hardened steel backing with bronze substrate and lead/indium overlay. Laser etched part numbers rather than typical stampings aid in significantly improved heat transfer and prevention of shell distortion. Formula 1 standards dictate extremely high tolerances, while Mahle’s attention to detail and chose of fine materials ensure worry free operation.

Mahle Motorsport German Tool Steel Wrist Pins

For ultimate strength and reliability, APR recommends upgrading to Mahle’s German tool steel wrist pins while upgrading connecting rods. If ordering APR’s Pistons, wrist pins are included.

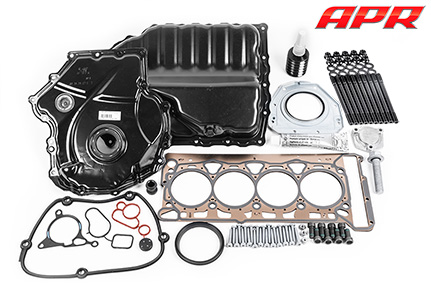

Install Kit

Upgrading connection rods requires disassembly of the engine, including several items designed for one time use only. Upon reassembly, new gaskets, stretch bolts, sealant and such are necessary to ensure years of reliable operation.

The APR Install kit simplifies the install process by providing each part necessary for an installation. This helps to ensure an effortless install process with little downtime. Each kit includes the following:

- ARP Head Studs and Bolts

- OEM Head Gasket

- OEM Flywheel Bolts

- OEM Oil Pan Sensor Cover

- OEM Oil Pan Sensor Washer

- OEM Oil Pan Sensor Nuts

- OEM Chain Side Gasket

- OEM Cam Tensioner Gasket

- OEM Oil Pan

- OEM Crankshaft Seal

- OEM Timing Case

- OEM Crank Bolt

- OEM Water Pump Union

- OEM Gaskets

- OEM Washers

- OEM Bolts

- OEM Plugs

- OEM Sealant

- OEM Victor Reinze Sealant

Choosing the Correct Rods

APR offers rods designed for the engine’s OEM pistons (Drop in Rods) and rods designed for use with APR’s upgraded Mahle Motorsport pistons. Depending on piston and engine code, different rods are required.

APR's Mahle Motorsport Pistons require part MS100053, designed for 23mm wrist pins.

OEM pistons require either 21 or 23mm wrist pins as outlined in the weight and application guide table. Use the included diagram to determine the engine code for rod selection.

APR’s found most engines are equipped with 21mm wrist pins if built before May of 2011 while engines built after May 2011 are equipped with 23mm wrist pins. Please make every effort to verify wrist pin size prior to rod purchase. In the event the wrong rods are chosen, please leave the box sealed and contact APR for further assistance.

| Engine | Engine Codes | Wrist Pin | Weight | Type | Part Number | Price(税別) | |

|---|---|---|---|---|---|---|---|

| Set of 4. | |||||||

| Weight includes APR2000 hardware. | |||||||

| *Most engines built before May 2011 contain connecting rods with 21mm wrist pins while most built after May 2011 contain 23mm wrist pins. Please verify prior to purchase. | |||||||

| EA888 2.0 TSI | CAW*, CBF*, CCT* & CCZ* | 21mm | 429.3g | Drop In for OEM Piston |

MS100050 | ¥200,000 | |

| EA888 2.0 TSI | CAW*, CBF*, CCT* & CCZ* | 23mm | 503.2g | Drop In For OEM or APR Piston |

MS100053 | ¥200,000 | |

| Rod | Part Number | Price(税別) |

|---|---|---|

| Set of 8. | ||

| All | Z1002179 | ¥40,000 |

| Size | Part Number | Price(税別) |

|---|---|---|

| Set of 4. If ordering APR Pistons, replacement wrist pins are included. | ||

| 21mm | MS100055 | ¥30,000 |

| 23mm | MS100058 | ¥30,000 |

| Rod | Part Number | Price(税別) |

|---|---|---|

| All | SK100002 | ¥130,000 |