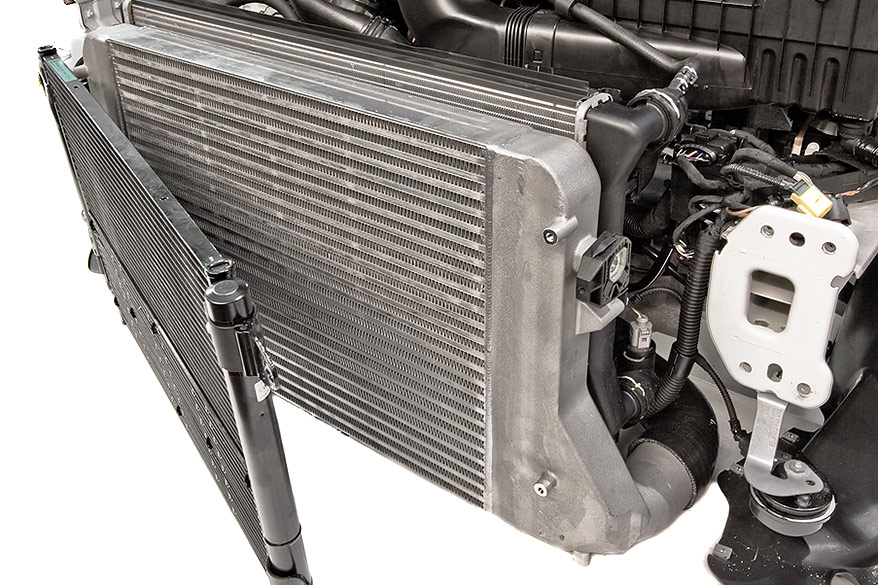

FMIC Components

Component Hightlights

End Tanks

Our all aluminum end-tanks are factory like cast pieces. A cast piece ensures consistency in the production process, which in turn guarantees proper fitment to the core. Once mated and welded to the core, all assemblies are pressure tested to 60psi. This intricate end tank design allows the APR intercooler to fit in the factory location with the stock air conditioning condensor and radiator bolted to it. No sheet metal endtanks here... You won't find this attention to detail in any other offering.

Intercooler Core

There are two primary core designs commonly used for cooling: the bar and plate design and the extruded tube. While both offer similar performance, a bar and plate intercooler is more efficent for cooling the intake charge temparature.

The size of the core is also very important. The APR intercooler for the Transverse 2.0T FSI is a massive 16.25" tall, 2.25" thick, and 23.2" wide. From a standard chipped car to a Stage III, this core is extremely efficient and does an outstanding job in reducing intake temps.

Silicone Connectors

The tooling for the silicon hoses is drawn up on Pro-Engineer and manufactured in house for precise fitment. Incorporated into the design is a recessed end, which allows the pipe to lie flush inside the hose, eliminating protruding edges that inhibit airflow.

Adaptor Coupler

The APR intercooler includes a specially designed and CNC-machined annodized aluminum coupler that allows the APR silicone intercooler hoses to connect to the original equipment connections just like the factory rubber lines. This design allows a quick-disconnects while maintaining a solid, leak-free connection.